Verralize enables on-site PFAS analysis and detection at 4 PPT in minutes.

Per- and polyfluoroalkyl substances (PFAS) contamination poses a dual challenge for environmental protection. In addition to removing these “forever chemicals” from the water supply, we first need to detect them quickly, accurately, and cost-effectively. Although remediation technology continues to advance, detection remains largely concentrated in specialized laboratories, creating bottlenecks in response times and increasing costs for utilities, industrial users, and remediation contractors.

Verralize has developed a revolutionary portable PFAS detection system that provides laboratory-like screening directly to the field. Using a proprietary nanocarbon-based electrochemical biosensor platform, the system can detect PFAS compounds at concentrations as low as 4 parts per trillion (ppt) in just 12 to 15 minutes, allowing immediate operational decisions to be made without the days or weeks typically required for laboratory analysis.

Detection challenges

Current standard methods for PFAS analysis primarily rely on liquid chromatography-mass spectrometry (LC-MS), which requires advanced laboratory infrastructure, highly trained personnel, and complex sample preparation protocols. Although LC-MS provides the final identification and quantification of PFAS compounds, this process typically takes days to weeks from sample collection to results and costs $300 to $500 per sample.

This poses significant operational challenges.

Delays in decision-making at remediation sites; Inability to quickly screen multiple locations; High costs that limit sampling frequency;

Coverage Sample storage and logistics complexity

Delivery bottlenecks in emergency response scenarios

These limitations create an urgent need for field-deployable screening tools that can provide actionable data in real time while maintaining sensitivity suitable for regulatory thresholds (currently as low as 4 ppt for certain compounds).

Verralize’s innovative approach

Verralize has developed a portable detection platform and PFAS field test kit that addresses these challenges through a novel combination of materials science, electrochemistry, and artificial intelligence.

core technology

At the heart of Verralize’s system is a multiplexed array of nanocarbon-based sensors, each functionalized with a unique ligand that selectively binds to specific PFAS molecules. The nanocarbon substrate offers excellent electronic properties that enable ultra-sensitive detection, and the special ligand chemistry ensures selectivity for targeted PFAS compounds.

Binding of PFAS molecules to these ligands induces measurable changes in the electrical conductivity across the nanocarbon surface. These signals are captured, processed through a proprietary algorithm, and converted into concentration values.

The main technical components are:

Sensor chemistry: Nanocarbon-based sensor with unique ligand functionalization for PFAS selectivity Detection mechanism: Electrochemical signaling with voltage-based readout Sensitivity: Routine detection at approximately 4 ppt, performance down to 1.5 ppt has been demonstrated under controlled conditions Multiplexing: Current platform accommodates 8 sensors per test, next generation 32-sensor array is in development Analysis time: From sample introduction to quantitation 12-15 minute results Analytes of interest: Initial validation of PFOA and PFOS, roadmap for coverage expansion

system architecture

A complete PFAS test kit consists of three main components:

Reusable Analyzer: A self-calibrating, portable instrument approximately the size of a medium-sized coffee thermos containing electronics, signal processing, and user interface components Disposable Sample Cup: A disposable container for water sample introduction Sensing Lid: A disposable consumable containing a multiplexed nanosensor array that interfaces with both the water sample and the analyzer

This modular design follows a commercial razor-and-blade model similar to point-of-care (POC) diagnostics, ensuring measurement consistency while preventing cross-contamination between tests. Analyzers connect to cloud-based applications to log data, control quality, and visualize results.

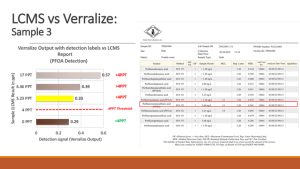

Validation and real performance

Verralize’s technology has undergone extensive laboratory validation and alpha testing across a variety of water matrices. To date, the following tests have been conducted:

In-house laboratory validation using spiked samples ranging in concentration from 1.5 ppt to 1,000 ppt Field testing across the New York tri-state region using various drinking water sources Alpha testing of approximately 2,000 water samples in collaboration with remediation and/or Alpha partners AI-driven algorithm improvements to correct for matrix effects and improve quantitative accuracy

Results demonstrated consistent detection capability at approximately 4 ppt in routine field use, and achieved sensitivity down to 1.5 ppt under controlled conditions in laboratory demonstrations. The system exhibits high selectivity for targeted PFAS compounds with minimal interference from common water components.

Dr. Saion Sinha, CEO of Verralize, explains, “Our nanocarbon-based sensor array and AI-driven analytics turn a drop of water into actionable intelligence in minutes. We are rigorous in our validation. Thousands of alpha samples have already demonstrated real-world performance, and with BioLargo as our distribution partner, we will accelerate our reach to the field and complete the extensive validation required for national rollout.”

Strategic partnership with BioLargo

Verralize has established a strategic partnership with BioLargo, a leader in innovative water treatment technology and developer of aqueous electrostatic concentrator (AEC) solutions for the removal and destruction of PFAS. This collaboration creates a powerful synergy between detection and remediation capabilities.

BioLargo will serve as Verralize’s alpha testing partner and future distribution channel, providing access to contaminated water samples for validation and leveraging its national presence and PFAS expertise for market penetration.

“Rapid PFAS detection in the field is a game-changer for the PFAS treatment market,” said Tonya Chandler, President of BioLargo Equipment Solutions & Technologies. “Verralize’s kit combines simplicity, affordability, and ability to differentiate between PFAS compounds and has proven invaluable to our clients. By integrating detection and treatment, real-time analysis fundamentally improves the speed and results of decision-making.”

This partnership enables a comprehensive approach to PFAS management, with Verralize’s rapid detection capabilities informing and optimizing BioLargo’s remediation efforts, creating an end-to-end solution for contamination assessment and treatment.

Applications and use cases

Verralize’s portable PFAS detection systems address multiple critical applications across water quality management.

Urban water monitoring: rapid screening of drinking water, monitoring of water treatment processes, verification of water distribution systems. Restoration site management: Innovative real-time monitoring, treatment efficacy verification, and site characterization. Industrial discharge compliance: pre-discharge screening and process control for industrial users. Emergency Response: If a release is suspected, immediately conduct a contamination assessment. Community Outreach: On-site testing of private wells and public water systems.

This technology is particularly valuable for time-sensitive applications where waiting days for test results can delay critical operational decisions or public health interventions.

Technology roadmap and future developments

Verralize is currently in the pre-commercial stage and is expected to go to market in Q1 2026. The development roadmap includes several key initiatives.

Expanded sensor count from 8 to 32 to increase coverage, especially for short-chain PFAS compounds Completed validation studies using samples from all 50 states Independent comparison studies against LC-MS reference methods Enhanced AI algorithms for matrix correction and interference removal Optimized consumable design for cost and environmental impact Integration with cloud-based data management systems for enterprise deployment

Market impact and positioning

The target market for field-deployable PFAS detection is over $500 million annually across utilities, remediation contractors, industrial dischargers, and compliance testing services. Verralize’s technology is a disruptive advancement in this space, delivering:

Speed: 12-15 minutes vs. days/weeks for clinical testing Sensitivity: Detection at regulatory relevant levels (4 ppt routine, proven down to 1.5 ppt) Simplicity: Designed for non-specialist operators with minimal training Portability: Field-deployable system that requires no clinical testing infrastructure Selectivity: Multiplexed sensor array identifies PFAS compounds Cost-effectiveness: Significantly reduces cost per test compared to clinical testing methods

Although the system is designed as a screening and operational decision support tool rather than a regulatory replacement for LC-MS confirmatory analysis, it fills a critical gap in PFAS management workflows by enabling rapid on-site assessments to guide sampling strategies, processing operations, and emergency response.

conclusion

As regulatory pressures increase and PFAS monitoring requirements expand, there is an increasing need for detection technologies that can be quickly deployed in the field. Verralize’s nanocarbon-based electrochemical biosensor platform represents a significant advance in addressing this challenge, bringing laboratory-level sensitivity to the field in a portable, easy-to-use format.

This technology dramatically reduces the time and cost barriers to PFAS testing, enabling more comprehensive monitoring, faster response to contamination events, and more efficient remediation efforts. When combined with advanced processing technologies such as BioLargo’s AEC system, it creates a powerful end-to-end solution for PFAS management.

For more information, to participate in the alpha testing program, or to inquire about a demo, please contact marilyn.b@verralize.com.

Source link