Roman concrete is pretty amazing. That is one of the main reasons why we know so much about Roman architecture today. So many structures built by the Romans still survive in some form thanks to their ingenious concrete and construction techniques.

But there’s still much we don’t know about how the Romans made concrete so strong and how they constructed their impressive buildings, homes, public baths, bridges, and roads.

you may like

Now, a new study led by researchers at the Massachusetts Institute of Technology (MIT) and published in Nature Communications sheds new light on Roman concrete and construction techniques.

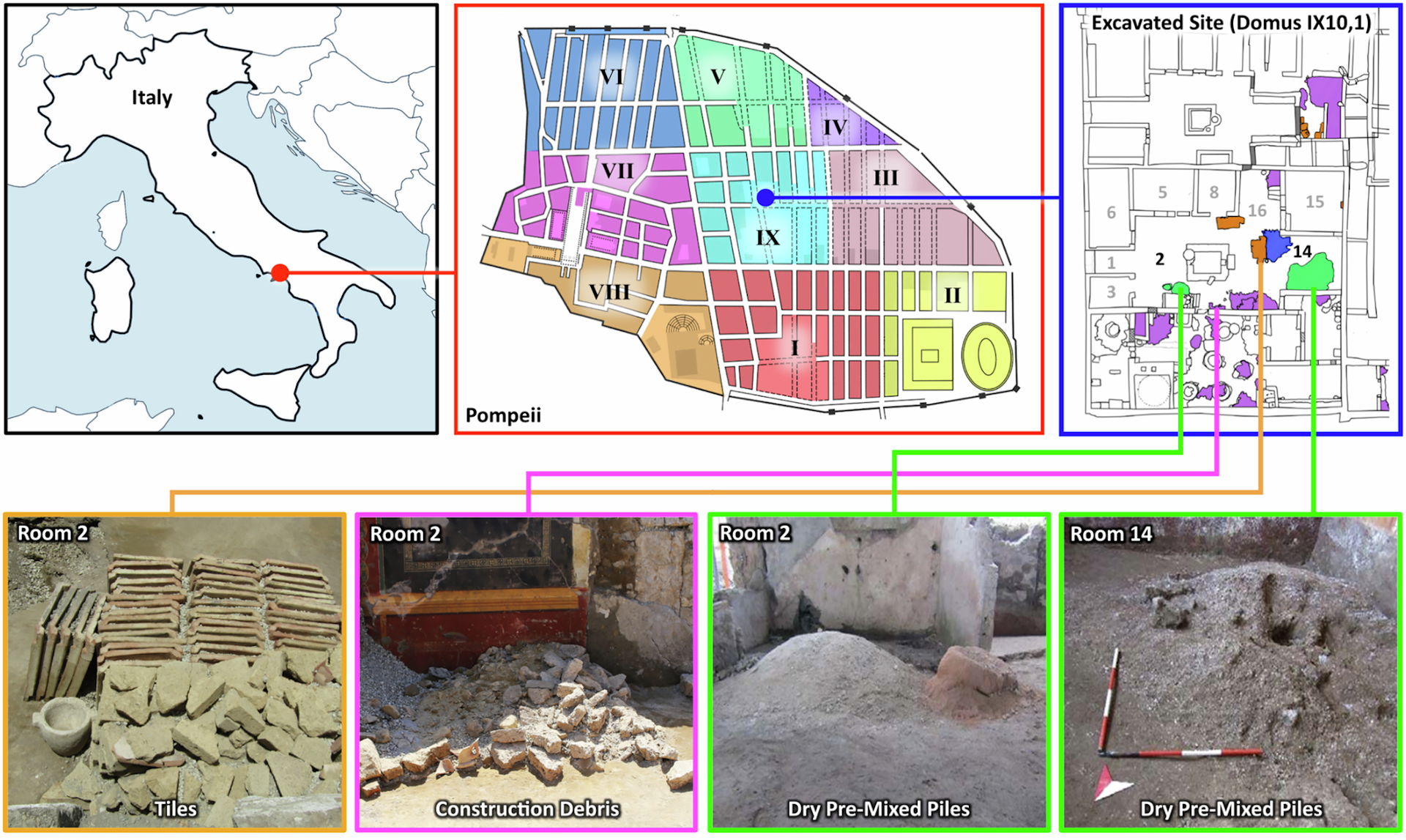

That’s thanks to details culled from mid-construction rooms in Pompeii, a workshop abandoned by workers following the eruption of Mount Vesuvius in 79 AD.

New clues about concrete making

The discovery of this particular building site made the news early last year.

When Mount Vesuvius exploded in the first century AD, builders were literally repairing houses in the middle of the city.

The unique finds included tiles that were separated for recycling and wine containers known as amphorae that were being reused to transport building materials.

But most importantly, it also included evidence that dry materials were prepared before being mixed to produce concrete.

This dry substance is the focus of new research. Having access to the actual materials before mixing provides a unique opportunity to understand the process of concrete production and how these materials react when water is added.

you may like

This rewritten our understanding of Roman concrete production.

self-healing concrete

The researchers behind this new paper studied the chemical composition of the material found in the field and defined several key elements. It’s an incredibly tiny piece of quicklime that changes our understanding of how concrete is made.

Quicklime is calcium oxide made by heating high-purity limestone (calcium carbonate).

The authors of this study explain that the process of mixing the concrete took place in the atrium of this house. Workers mixed dry lime (ground lime) with pozzolana (volcanic ash).

When water is added, a chemical reaction generates heat. In other words, it was an exothermic reaction. This is known as “hot mixing” and results in a completely different type of concrete than what you can get at a hardware store.

When water is added to quicklime, heat is generated and something called slaked lime is produced. The researchers identified small undissolved “lime lumps” within the slaked lime that retain the quicklime’s reactivity. When cracks form in this concrete, the lime chunks react with water to repair the cracks.

In other words, this form of Roman concrete can literally repair itself.

old and new techniques

However, it is difficult to know how widespread this method was in ancient Rome.

Much of our understanding of Roman concrete is based on the writings of the ancient Roman architect Vitruvius.

He advised the use of pozzolana mixed with lime, but the document was thought to make no mention of heated mixing.

However, if we look at another Roman author, Pliny the Elder, we find a clear explanation of the reaction between quicklime and water, which is the basis of the exothermic reaction associated with hot-mixed concrete.

Therefore, although the ancients had knowledge of hot mixing, little is known about how widespread this technique became.

Perhaps more important are the text’s details about experiments with various blends of sand, pozzolana, and lime that led to the mixture used by Pompeii’s builders.

The MIT team had previously discovered limestone blocks (tiny pieces of quicklime) at the Roman ruins of Privernum, about 30 miles (43 kilometers) north of Pompeii.

It is also noteworthy that repair of cracks was observed in the concrete of the tomb of the noblewoman Caecilia Metella on the Via Appia (a famous Roman road) outside Rome.

This new study from Pompeii proves that hot mixing occurred and how it helped improve Roman concrete, allowing scholars to look for examples of concrete cracks being repaired in this way.

doubts remain

Overall, this new research is interesting, but we must resist the assumption that all Roman architecture was built to a high standard.

The ancient Romans were able to make excellent concrete mortar, but as Pliny the Elder pointed out, poor mortar was the cause of Roman buildings collapsing. So just because you could make a good mortar doesn’t mean you always did it.

Of course, questions remain.

Can we generalize from this new study’s single example from Pompeii in 79 AD to interpret all forms of Roman concrete?

Does it show progress from Vitruvius, which I wrote about a while ago?

Was the use of quicklime to make stronger concrete in this Pompeii house, built in 79 AD, a response to earthquakes in the area that would cause future cracks?

To answer any of these questions, further research is needed to ascertain the prevalence of limescale in Roman concrete more generally and to determine where Roman concrete has repaired itself.

This edited article is republished from The Conversation under a Creative Commons license. Read the original article.

Source link